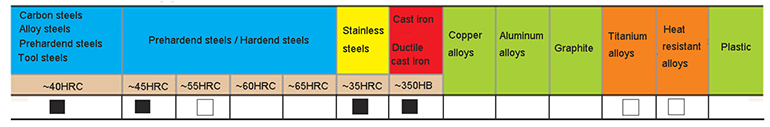

One tool for many materials and various applications

Processing multi-material with hardness ≤ 45 HRC

Ideal for small batch and varied production.

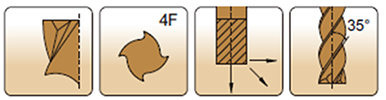

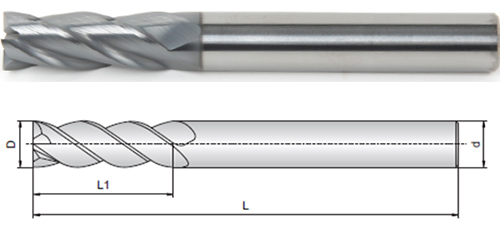

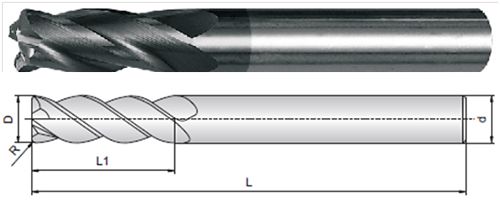

A sharp-edged carbide end mill, used for milling workpiece without internal corners and side milling.

Ultrafine particle cemented carbide.

PU (AlCrN) coating with high heat resistance and high lubricity.

Great toughness,sharp edges,Provide easy cutting.

Outstanding chip control by excellent geometric angle and cutting edge design.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D1-3-50-D4-4F MGE | - | 1 | 3 | 50 | 4 | 4 |

| D1.5-4-50-D4-4F MGE | - | 1.5 | 4 | 50 | 4 | 4 |

| D2-6-50-D4-4F MGE | - | 2 | 6 | 50 | 4 | 4 |

| D2.5-7.5-50-D4-4F MGE | - | 2.5 | 7.5 | 50 | 4 | 4 |

| D3-8-50-D4-4F MGE | - | 3 | 8 | 50 | 4 | 4 |

| D4-11-50-4F MGE | - | 4 | 11 | 50 | 4 | 4 |

| D4-16-75-4F MGE | - | 4 | 16 | 75 | 4 | 4 |

| D4-20-100-4F MGE | - | 4 | 20 | 100 | 4 | 4 |

| D5-15-50-D6-4F MGE | - | 5 | 15 | 50 | 6 | 4 |

| D5-20-75-D6-4F MGE | - | 5 | 20 | 75 | 6 | 4 |

| D6-15-50-4F MGE | - | 6 | 15 | 50 | 6 | 4 |

| D6-24-75-4F MGE | - | 6 | 24 | 75 | 6 | 4 |

| D6-30-100-4F MGE | - | 6 | 30 | 100 | 6 | 4 |

| D8-20-60-4F MGE | - | 8 | 20 | 60 | 8 | 4 |

| D8-25-75-4F MGE | - | 8 | 25 | 75 | 8 | 4 |

| D8-35-100-4F MGE | - | 8 | 35 | 100 | 8 | 4 |

| D10-25-75-4F MGE | - | 10 | 25 | 75 | 10 | 4 |

| D10-40-100-4F MGE | - | 10 | 40 | 100 | 10 | 4 |

| D12-30-75-4F MGE | - | 12 | 30 | 75 | 12 | 4 |

| D12-45-100-4F MGE | - | 12 | 45 | 100 | 12 | 4 |

| D14-45-100-4F MGE | - | 14 | 45 | 100 | 14 | 4 |

| D16-45-100-4F MGE | - | 16 | 45 | 100 | 16 | 4 |

| D16-65-150-4F MGE | - | 16 | 65 | 150 | 16 | 4 |

| D20-45-100-4F MGE | - | 20 | 45 | 100 | 20 | 4 |

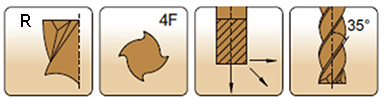

To avoid stress concentration at the internal corners of the workpiece, a round-cornered R-type

carbide end mill is used for milling workpieces with internal corners.

Ultrafine particle cemented carbide.

PU (AlCrN) coating with high heat resistance and high lubricity.

Great toughness,sharp edges,Provide easy cutting.

The design of high rigidity section and rounded corner R with 35° strong spiral angle

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D1R0.2-3-50-D4-4F MGR | 0.2 | 1 | 3 | 50 | 4 | 4 |

| D1.5R0.2-4-50-D4-4F MGR | 0.2 | 1.5 | 4 | 50 | 4 | 4 |

| D2R0.2-6-50-D4-4F MGR | 0.2 | 2 | 6 | 50 | 4 | 4 |

| D3R0.2-8-50-D4-4F MGR | 0.2 | 3 | 8 | 50 | 4 | 4 |

| D4R0.2-11-50-4F MGR | 0.2 | 4 | 11 | 50 | 4 | 4 |

| D4R0.5-11-50-4F MGR | 0.5 | 4 | 11 | 50 | 4 | 4 |

| D4R0.5-16-75-4F MGR | 0.5 | 4 | 16 | 75 | 4 | 4 |

| D4R1-11-50-4F MGR | 1 | 4 | 11 | 50 | 4 | 4 |

| D4R1-16-75-4F MGR | 1 | 4 | 16 | 75 | 4 | 4 |

| D6R0.2-15-50-4F MGR | 0.2 | 6 | 15 | 50 | 6 | 4 |

| D6R0.2-24-75-4F MGR | 0.2 | 6 | 24 | 75 | 6 | 4 |

| D6R0.2-30-100-4F MGR | 0.2 | 6 | 30 | 100 | 6 | 4 |

| D6R0.5-15-50-4F MGR | 0.5 | 6 | 15 | 50 | 6 | 4 |

| D6R0.5-24-75-4F MGR | 0.5 | 6 | 24 | 75 | 6 | 4 |

| D6R0.5-30-100-4F MGR | 0.5 | 6 | 30 | 100 | 6 | 4 |

| D6R1-15-50-4F MGR | 1 | 6 | 15 | 50 | 6 | 4 |

| D6R1-24-75-4F MGR | 1 | 6 | 24 | 75 | 6 | 4 |

| D6R1-30-100-4F MGR | 1 | 6 | 30 | 100 | 6 | 4 |

| D8R0.5-20-60-4F MGR | 0.5 | 8 | 20 | 60 | 8 | 4 |

| D8R1-24-60-4F MGR | 1 | 8 | 24 | 60 | 8 | 4 |

| D8R1-24-75-4F MGR | 1 | 8 | 24 | 75 | 8 | 4 |

| D8R1-32-100-4F MGR | 1 | 8 | 32 | 100 | 8 | 4 |

| D8R2-24-60-4F MGR | 2 | 8 | 24 | 60 | 8 | 4 |

| D8R2-24-75-4F MGR | 2 | 8 | 24 | 75 | 8 | 4 |

| D8R2-32-100-4F MGR | 2 | 8 | 32 | 100 | 8 | 4 |

| D8R3-24-60-4F MGR | 3 | 8 | 24 | 60 | 8 | 4 |

| D8R3-24-75-4F MGR | 3 | 8 | 24 | 75 | 8 | 4 |

| D8R3-32-100-4F MGR | 3 | 8 | 32 | 100 | 8 | 4 |

| D10R0.5-25-75-4F MGR | 0.5 | 10 | 25 | 75 | 10 | 4 |

| D10R1-30-75-4F MGR | 1 | 10 | 30 | 75 | 10 | 4 |

| D10R1-35-100-4F MGR | 1 | 10 | 35 | 100 | 10 | 4 |

| D10R2-30-75-4F MGR | 2 | 10 | 30 | 75 | 10 | 4 |

| D10R2-35-100-4F MGR | 2 | 10 | 35 | 100 | 10 | 4 |

| D10R3-30-75-4F MGR | 3 | 10 | 30 | 75 | 10 | 4 |

| D10R3-35-100-4F MGR | 3 | 10 | 35 | 100 | 10 | 4 |

| D12R0.5-30-75-4F MGR | 0.5 | 12 | 30 | 75 | 12 | 4 |

| D12R1-30-75-4F MGR | 1 | 12 | 30 | 75 | 12 | 4 |

| D12R1-40-100-4F MGR | 1 | 12 | 40 | 100 | 12 | 4 |

| D12R2-30-75-4F MGR | 2 | 12 | 30 | 75 | 12 | 4 |

| D12R2-40-100-4F MGR | 2 | 12 | 40 | 100 | 12 | 4 |

| D12R3-30-75-4F MGR | 3 | 12 | 30 | 75 | 12 | 4 |

| D12R3-40-100-4F MGR | 3 | 12 | 40 | 100 | 12 | 4 |

| D16R1-45-100-4F MGR | 1 | 16 | 45 | 100 | 16 | 4 |

| D16R1-60-150-4F MGR | 1 | 16 | 60 | 150 | 16 | 4 |

| D16R3-45-100-4F MGR | 3 | 16 | 45 | 100 | 16 | 4 |

| D16R3-60-150-4F MGR | 3 | 16 | 60 | 150 | 16 | 4 |

| D20R1-50-100-4F MGR | 1 | 20 | 50 | 100 | 20 | 4 |

| D20R1-70-150-4F MGR | 1 | 20 | 70 | 150 | 20 | 4 |

| D20R3-50-100-4F MGR | 3 | 20 | 50 | 100 | 20 | 4 |

| D20R3-70-150-4F MGR | 3 | 20 | 70 | 150 | 20 | 4 |

Ultrafine particle cemented carbide.

PU (AlCrN) coating with high heat resistance and high lubricity.

Great toughness and rigidity,sharp edges,Provide easy cutting and perfect surface,Suitable for finishing with light cutting.

The design of high rigidity section and rounded corner R with 30° strong spiral angle.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter | |||

| D1R0.5-2-50-D4-2F MGB | 0.5 | 1 | 2 | 50 | 4 | 2 |

| D1.5R0.75-3-50-D4-2F MGB | 0.75 | 1.5 | 3 | 50 | 4 | 2 |

| D2R1-4-50-D4-2F MGB | 1 | 2 | 4 | 50 | 4 | 2 |

| D3R1.5-6-50-D4-2F MGB | 1 | 3 | 6 | 50 | 4 | 2 |

| D4R2-8-50-2F MGB | 2 | 4 | 8 | 50 | 4 | 2 |

| D4R2-8-75-2F MGB | 2 | 4 | 8 | 75 | 4 | 2 |

| D4R2-8-100-2F MGB | 2 | 4 | 8 | 100 | 4 | 2 |

| D6R3-12-50-2F MGB | 3 | 6 | 12 | 50 | 6 | 2 |

| D6R3-12-75-2F MGB | 3 | 6 | 12 | 75 | 6 | 2 |

| D6R3-12-100-2F MGB | 3 | 6 | 12 | 100 | 6 | 2 |

| D8R4-16-60-2F MGB | 4 | 8 | 16 | 60 | 8 | 2 |

| D8R4-16-75-2F MGB | 4 | 8 | 16 | 75 | 8 | 2 |

| D8R4-16-100-2F MGB | 4 | 8 | 16 | 100 | 8 | 2 |

| D10R5-20-75-2F MGB | 5 | 10 | 20 | 75 | 10 | 2 |

| D10R5-20-100-2F MGB | 5 | 10 | 20 | 100 | 10 | 2 |

| D12R6-24-75-2F MGB | 6 | 12 | 24 | 75 | 12 | 2 |

| D12R6-24-100-2F MGB | 6 | 12 | 24 | 100 | 12 | 2 |

Steel , Cast iron -----Side milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

carbon steel,alloy steel (<35HRC) |

ap≤1.5D | 180 | rotate speed (min-1) |

38000 | 28000 | 19110 | 14330 | 9550 | 7170 | 5730 | 4780 | 3580 | 2870 |

| ae≤0.15D | feed speed (mm/min) |

2600 | 2240 | 2140 | 2060 | 1830 | 1860 | 1830 | 1720 | 1720 | 1720 | |||

| alloy steel (35-48HRC) |

ap≤1D | 130 | rotate speed (min-1) |

22000 | 16800 | 13800 | 10350 | 6900 | 5180 | 4140 | 3450 | 2590 | 2070 | |

| ae≤0.12D | feed speed (mm/min) |

1480 | 1340 | 1210 | 1160 | 1100 | 1240 | 1130 | 1010 | 830 | 750 | |||

|

stainless steel | ap≤1.5D | 130 | rotate speed (min-1) |

22000 | 16800 | 13800 | 10350 | 6900 | 5180 | 4140 | 3450 | 2590 | 2070 |

| ae≤0.15D | feed speed (mm/min) |

1480 | 1340 | 1380 | 1330 | 1190 | 1300 | 1230 | 1170 | 980 | 910 | |||

|

gray cast iron nodular cast iron (<32HRC) |

ap≤1.5D | 160 | rotate speed (min-1) |

22000 | 16800 | 16990 | 12740 | 8490 | 6370 | 5100 | 4250 | 3190 | 2550 |

| ae≤0.15D | feed speed (mm/min) |

1880 | 1780 | 1700 | 1630 | 1630 | 1500 | 1410 | 1360 | 1210 | 1120 | |||

| High alloy cast iron (35-45HRC) |

ap≤1D | 140 | rotate speed (min-1) |

22000 | 16800 | 14860 | 11150 | 7430 | 5570 | 4460 | 3720 | 2790 | 2230 | |

| ae≤0.12D | feed speed (mm/min) |

1580 | 1480 | 1310 | 1340 | 1340 | 1250 | 1160 | 1120 | 1000 | 910 | |||

Steel , Cast iron -----Profiling milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | |

|

carbon steel,alloy steel (<35HRC) |

ap≤0.2D | 160 | rotate speed (min-1) |

30000 | 22000 | 16000 | 12740 | 8490 | 6370 | 5100 | 4250 |

| ae≤0.3D | feed speed (mm/min) |

1200 | 1100 | 1050 | 1020 | 1020 | 1020 | 1020 | 1020 | |||

| alloy steel (35-48HRC) |

ap≤0.15D | 120 | rotate speed (min-1) |

17800 | 14800 | 13800 | 9550 | 6370 | 4780 | 3820 | 3190 | |

| ae≤0.15D | feed speed (mm/min) |

760 | 670 | 620 | 610 | 610 | 610 | 610 | 610 | |||

|

stainless steel | ap≤0.2D | 110 | rotate speed (min-1) |

17800 | 14800 | 13800 | 8760 | 5840 | 4380 | 3500 | 2920 |

| ae≤0.2D | feed speed (mm/min) |

760 | 670 | 620 | 610 | 610 | 610 | 610 | 610 | |||

|

gray cast iron nodular cast iron (<32HRC) |

ap≤0.2D | 140 | rotate speed (min-1) |

17800 | 14800 | 13800 | 11150 | 7430 | 5570 | 4460 | 3720 |

| ae≤0.2D | feed speed (mm/min) |

840 | 820 | 800 | 780 | 820 | 800 | 800 | 820 | |||

| High alloy cast iron (35-45HRC) |

ap≤0.1D | 120 | rotate speed (min-1) |

17800 | 14800 | 13800 | 9550 | 6370 | 4780 | 3820 | 3190 | |

| ae≤0.1D | feed speed (mm/min) |

760 | 680 | 640 | 610 | 660 | 670 | 650 | 670 | |||

| Carbide End Mills MN | for aluminum alloys |

| Carbide End Mills MS | for heat-resisting alloys |