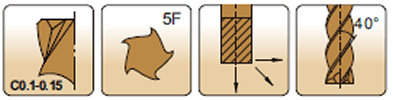

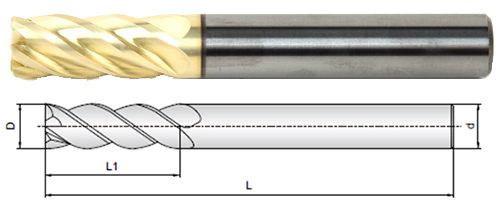

To avoid resonance, reduce vibration, improve machining surface quality, and increase tool life,five edges are slightly unevenly distributed along the circumference.

Using the PSC (AlTiCrSiN) new special coating effectively avoids tool adhesion during machining and improves tool durability.

Ideal for medium to large batch production

PSC (AlTiCrSiN) new special coating.

A five-edge design, specifically engineered for processing difficult-to-machine materials, adopts a slightly non-uniform distribution along the circumference to avoid resonance, enhance machining surface quality, and increase tool life.

Ultrafine particle cemented carbide .

Great toughness,sharp edges,Provideeasy

cutting.

Outstanding chip control by excellent

geometric angle and edge design.

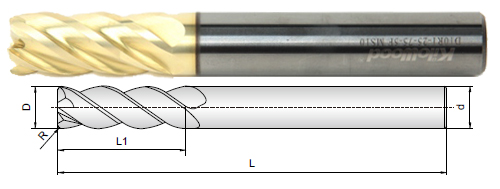

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D2-5-50-D4-5F MSE | - | 2 | 5 | 50 | 4 | 5 |

| D2-5-75-D4-5F MSE | - | 2 | 5 | 75 | 4 | 5 |

| D3-8-50-D4-5F MSE | - | 3 | 8 | 50 | 4 | 5 |

| D3-8-75-D4-5F MSE | - | 3 | 8 | 75 | 4 | 5 |

| D4-10-50-5F MSE | - | 4 | 10 | 50 | 4 | 5 |

| D4-10-75-5F MSE | - | 4 | 10 | 75 | 4 | 5 |

| D6-15-50-5F MSE | - | 6 | 15 | 50 | 6 | 5 |

| D6-15-75-5F MSE | - | 6 | 15 | 75 | 6 | 5 |

| D8-20-60-5F MSE | - | 8 | 20 | 60 | 8 | 5 |

| D8-20-75-5F MSE | - | 8 | 20 | 75 | 8 | 5 |

| D10-25-75-5F MSE | - | 10 | 25 | 75 | 10 | 5 |

| D10-25-100-5F MSE | - | 10 | 25 | 100 | 10 | 5 |

| D12-30-75-5F MSE | - | 12 | 30 | 75 | 12 | 5 |

| D12-30-100-5F MSE | - | 12 | 30 | 100 | 12 | 5 |

| D16-40-100-5F MSE | - | 16 | 40 | 100 | 16 | 5 |

| D16-40-150-5F MSE | - | 16 | 40 | 150 | 16 | 5 |

| D20-50-100-5F MSE | - | 20 | 50 | 100 | 20 | 5 |

| D20-50-150-5F MSE | - | 20 | 50 | 150 | 20 | 5 |

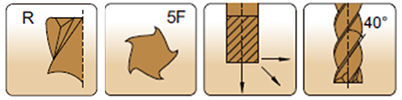

Difficult-to-machine materials such as heat-resistant alloys, titanium alloys, and nickel-based alloys special

five-edge carbide end mill with rounded corner.

PSC (AlTiCrSiN) new special coating.

A five-edge design, specifically engineered for processing difficult-to-machine materials, adopts a slightly non-uniform distribution along the circumference to avoid resonance, enhance machining surface quality, and increase tool life.

Ultrafine particle cemented carbide .

Great toughness,sharp edges,Provideeasy

cutting.

Outstanding chip control by excellent

geometric angle and edge design.

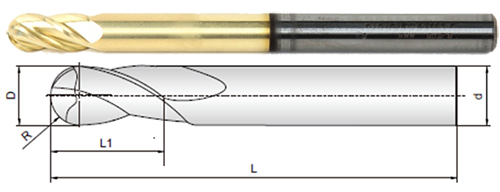

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D4R0.5-10-50-5F MSR | 0.5 | 4 | 10 | 50 | 4 | 5 |

| D4R0.5-10-75-5F MSR | 0.5 | 4 | 10 | 75 | 4 | 5 |

| D4R1-10-50-5F MSR | 1 | 4 | 10 | 50 | 4 | 5 |

| D4R1-10-75-5F MSR | 1 | 4 | 10 | 75 | 4 | 5 |

| D6R0.5-15-50-5F MSR | 0.5 | 6 | 15 | 50 | 6 | 5 |

| D6R0.5-15-75-5F MSR | 0.5 | 6 | 15 | 75 | 6 | 5 |

| D6R1-15-50-5F MSR | 1 | 6 | 15 | 50 | 6 | 5 |

| D6R1-15-75-5F MSR | 1 | 6 | 15 | 75 | 6 | 5 |

| D8R0.5-20-60-5F MSR | 0.5 | 8 | 20 | 60 | 8 | 5 |

| D8R0.5-20-75-5F MSR | 0.5 | 8 | 20 | 75 | 8 | 5 |

| D8R1-20-60-5F MSR | 1 | 8 | 20 | 60 | 8 | 5 |

| D8R1-20-75-5F MSR | 1 | 8 | 20 | 75 | 8 | 5 |

| D8R2-20-60-5F MSR | 2 | 8 | 20 | 60 | 8 | 5 |

| D8R2-20-75-5F MSR | 2 | 8 | 20 | 75 | 8 | 5 |

| D10R0.5-25-75-5F MSR | 0.5 | 10 | 25 | 75 | 10 | 5 |

| D10R0.5-25-100-5F MS | 0.5 | 10 | 25 | 100 | 10 | 5 |

| D10R1-25-75-5F MSR | 1 | 10 | 25 | 75 | 10 | 5 |

| D10R1-25-100-5F MSR | 1 | 10 | 25 | 100 | 10 | 5 |

| D10R2-25-75-5F MSR | 2 | 10 | 25 | 75 | 10 | 5 |

| D10R2-25-100-5F MSR | 2 | 10 | 25 | 100 | 10 | 5 |

| D12R0.5-30-75-5F MSR | 0.5 | 12 | 30 | 75 | 12 | 5 |

| D12R0.5-30-100-5F MS | 0.5 | 12 | 30 | 100 | 12 | 5 |

| D12R1-30-75-5F MSR | 1 | 12 | 30 | 75 | 12 | 5 |

| D12R1-30-100-5F MSR | 1 | 12 | 30 | 100 | 12 | 5 |

| D12R2-30-75-5F MSR | 2 | 12 | 30 | 75 | 12 | 5 |

| D12R2-30-100-5F MSR | 2 | 12 | 30 | 100 | 12 | 5 |

| D12R3-30-75-5F MSR | 3 | 12 | 30 | 75 | 12 | 5 |

| D12R3-30-100-5F MSR | 3 | 12 | 30 | 100 | 12 | 5 |

| D16R1-40-100-5F MSR | 1 | 16 | 40 | 100 | 16 | 5 |

| D16R1-40-150-5F MSR | 1 | 16 | 40 | 150 | 16 | 5 |

| D16R2-40-100-5F MSR | 2 | 16 | 40 | 100 | 16 | 5 |

| D16R2-40-150-5F MSR | 2 | 16 | 40 | 150 | 16 | 5 |

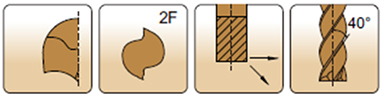

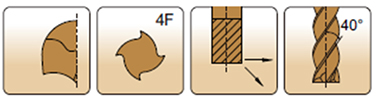

Difficult-to-machine materials such as heat-resistant alloys, titanium alloys, and nickel-based alloys special

double-edged (≤3mm) or four-edge (>3mm) carbide ball nose end mill.

PSC (AlTiCrSiN) new special coating.

Ultrafine particle cemented carbide.

Great toughness,sharp edges,Provide easy cutting and perfect surface,Suitable for finishing with light cutting.

The design of high rigidity section and tip with 40° strong spiral angle.

A four-edge design (>3mm) improves machining surface quality and extends tool life.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D3R1-4-50-D4-2F MSB | 1 | 2 | 4 | 50 | 4 | 2 |

| D2R1-4-75-D4-2F MSB | 1 | 2 | 4 | 75 | 4 | 2 |

| D3R1.5-6-50-D4-2F MSB | 1.5 | 3 | 6 | 50 | 4 | 2 |

| D3R1.5-6-75-D4-2F MSB | 1.5 | 3 | 6 | 75 | 4 | 2 |

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D4R2-8-50-4F MSB | 2 | 4 | 8 | 50 | 4 | 4 |

| D4R2-8-75-4F MSB | 2 | 4 | 8 | 75 | 4 | 4 |

| D6R3-12-50-4F MSB | 3 | 6 | 12 | 50 | 6 | 4 |

| D6R3-12-75-4F MSB | 3 | 6 | 12 | 75 | 6 | 4 |

| D8R4-16-60-4F MSB | 4 | 8 | 16 | 60 | 8 | 4 |

| D8R4-16-75-4F MSB | 4 | 8 | 16 | 75 | 8 | 4 |

| D10R5-20-75-4F MSB | 5 | 10 | 20 | 75 | 10 | 4 |

| D10R5-20-100-4F MSB | 5 | 10 | 20 | 100 | 10 | 4 |

High temperature alloy,titanium alloy——Side milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

high temperature alloy, titanium alloy |

ap≤0.8D | 20-50 | rotate speed (r/min) |

9500 | 4750 | 3150 | 2350 | 1550 | 1200 | 950 | 800 | 600 | 500 |

| ae≤0.05D | feed speed (mm/min) |

380 | 280 | 190 | 190 | 130 | 140 | 115 | 110 | 95 | 95 | |||

High temperature alloy,titanium alloy —— Slot mill.

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

high temperature alloy, titanium alloy |

ap≤0.8D | 20-50 | rotate speed (r/min) |

9500 | 4750 | 3150 | 2350 | 1550 | 1200 | 950 | 800 | 600 | 500 |

| ae≤0.05D | feed speed (mm/min) |

300 | 220 | 150 | 150 | 100 | 110 | 90 | 90 | 75 | 75 | |||

high temperature alloy,titanium alloy —— Profiling milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

high temperature alloy, titanium alloy |

ap≤0.6D | 20-50 | rotate speed (r/min) |

9500 | 4750 | 3150 | 2350 | 1550 | 1200 | 950 | 800 | 600 | 500 |

| ae≤0.03D | feed speed (mm/min) |

380 | 280 | 190 | 190 | 130 | 140 | 115 | 110 | 95 | 95 | |||

| Carbide End Mills MG | for multi-material |

| Carbide End Mills MN | for aluminum alloys |