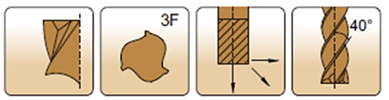

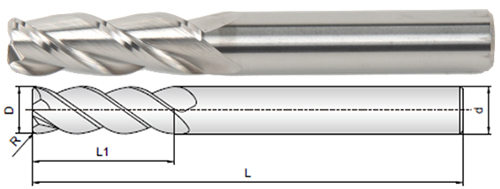

The unique three-flute design increases the available space for effective removal of iron chips without compromising the tool’s rigidity.

The grooves of the MN end mills have been polished to enhance processing efficiency and chip evacuation, as well as improve the surface finish of the workpiece.

Ideal for medium to large batch production

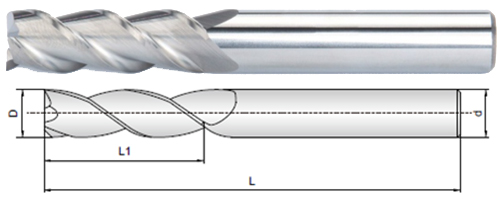

Non-coating.

Ultrafine particle cemented carbide .

Special cutting edge design with excellent

geometric angle.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D1-3-50-D4-3F MNE | - | 1 | 3 | 50 | 4 | 3 |

| D1.5-4.5-50-D4-3F MNE | - | 1.5 | 4.5 | 50 | 4 | 3 |

| D2-6-50-D4-3F MNE | - | 2 | 6 | 50 | 4 | 3 |

| D3-9-50-D4-3F MNE | - | 3 | 9 | 50 | 4 | 3 |

| D4-12-50-3F MNE | - | 4 | 12 | 50 | 4 | 2 |

| D4-16-75-3F MNE | - | 4 | 16 | 75 | 4 | 3 |

| D4-20-100-3F MNE | - | 4 | 20 | 100 | 4 | 3 |

| D5-15-50-D6-3F MNE | - | 5 | 15 | 50 | 6 | 3 |

| D5-20-75-D6-3F MNE | - | 5 | 20 | 75 | 6 | 3 |

| D5-25-100-D6-3F MNE | - | 5 | 25 | 100 | 6 | 3 |

| D6-18-50-3F MNE | - | 6 | 18 | 50 | 6 | 3 |

| D6-24-75-3F MNE | - | 6 | 24 | 75 | 6 | 3 |

| D6-30-100-3F MNE | - | 6 | 30 | 30 | 6 | 3 |

| D8-24-60-3F MNE | - | 8 | 24 | 60 | 8 | 3 |

| D8-25-75-3F MNE | - | 8 | 25 | 75 | 8 | 3 |

| D8-35-100-3F MNE | - | 8 | 35 | 100 | 8 | 3 |

| D10-30-75-3F MNE | - | 10 | 30 | 75 | 10 | 3 |

| D10-40-100-3F MNE | - | 10 | 40 | 100 | 10 | 3 |

| D12-36-75-3F MNE | - | 12 | 36 | 75 | 12 | 3 |

| D12-45-100-3F MNE | - | 12 | 45 | 100 | 12 | 3 |

| D16-45-100-3F MNE | - | 16 | 45 | 100 | 16 | 3 |

| D16-65-150-3F MNE | - | 16 | 65 | 150 | 16 | 3 |

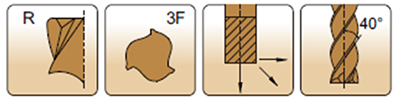

Non-coating.

Ultrafine particle cemented carbide .

Special cutting edge design with excellent geometric angle.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d& | |||

| D1R0.2-3-50-D4-3F MNR | 0.2 | 1 | 3 | 50 | 4 | 3 |

| D1.5R0.2-4.5-50-D4-3F MNR | 0.2 | 1.5 | 4.5 | 50 | 4 | 3 |

| D2R0.2-6-50-D4-3F MNR | 0.2 | 2 | 6 | 50 | 4 | 3 |

| D3R0.2-9-50-D4-3F MNR | 0.2 | 3 | 9 | 50 | 4 | 3 |

| D4R0.2-12-50-3F MNR | 0.2 | 4 | 12 | 50 | 4 | 3 |

| D4R0.5-12-50-3F MNR | 0.5 | 4 | 12 | 50 | 4 | 3 |

| D4R0.5-16-75-3F MNR | 0.5 | 4 | 16 | 75 | 4 | 3 |

| D4R1-11-50-3F MNR | 1 | 4 | 11 | 50 | 4 | 3 |

| D4R1-16-75-3F MNR | 1 | 4 | 16 | 75 | 4 | 3 |

| D6R0.2-18-50-3F MNR | 0.2 | 6 | 18 | 50 | 6 | 3 |

| D6R0.2-24-75-3F MNR | 0.2 | 6 | 24 | 75 | 6 | 3 |

| D6R0.2-30-100-3F MNR | 0.2 | 6 | 30 | 100 | 6 | 3 |

| D6R0.5-18-50-3F MNR | 0.5 | 6 | 18 | 50 | 6 | 3 |

| D6R0.5-24-75-3F MNR | 0.5 | 6 | 24 | 75 | 6 | 3 |

| D6R0.5-30-100-3F MNR | 0.5 | 6 | 30 | 100 | 6 | 3 |

| D6R1-18-50-3F MNR | 1 | 6 | 18 | 50 | 6 | 3 |

| D6R1-24-75-3F MNR | 1 | 6 | 24 | 75 | 6 | 3 |

| D6R1-30-100-3F MNR | 1 | 6 | 30 | 100 | 6 | 3 |

| D8R0.5-24-60-3F MNR | 0.5 | 8 | 24 | 60 | 8 | 3 |

| D8R0.5-24-75-3F MNR | 0.5 | 8 | 24 | 75 | 8 | 3 |

| D8R0.5-32-100-3F MNR | 0.5 | 8 | 32 | 100 | 8 | 3 |

| D8R1-24-60-3F MNR | 1 | 8 | 24 | 60 | 8 | 3 |

| D8R1-24-75-3F MNR | 1 | 8 | 24 | 75 | 8 | 3 |

| D8R1-32-100-3F MNR | 1 | 8 | 32 | 100 | 8 | 3 |

| D8R2-24-60-3F MNR | 2 | 8 | 24 | 60 | 8 | 3 |

| D8R2-24-75-3F MNR | 2 | 8 | 24 | 75 | 8 | 3 |

| D8R2-32-100-3F MNR | 2 | 8 | 32 | 100 | 8 | 3 |

| D8R3-24-60-3F MNR | 3 | 8 | 24 | 60 | 8 | 3 |

| D8R3-24-75-3F MNR | 3 | 8 | 24 | 75 | 8 | 3 |

| D8R3-32-100-3F MNR | 3 | 8 | 32 | 100 | 8 | 3 |

| D10R0.5-30-75-3F MNR | 0.5 | 10 | 30 | 75 | 10 | 3 |

| D10R0.5-35-100-3F MNR | 0.5 | 10 | 35 | 100 | 10 | 3 |

| D10R1-30-75-3F MNR | 1 | 10 | 30 | 75 | 10 | 3 |

| D10R1-35-100-3F MNR | 1 | 10 | 35 | 100 | 10 | 3 |

| D10R3-30-75-3F MNR | 3 | 10 | 30 | 75 | 10 | 3 |

| D10R3-35-100-3F MNR | 3 | 10 | 35 | 100 | 10 | 3 |

| D12R0.5-30-75-3F MNR | 0.5 | 12 | 30 | 75 | 12 | 3 |

| D12R0.5-40-100-3F MNR | 0.5 | 12 | 40 | 100 | 12 | 3 |

| D12R1-30-75-3F MNR | 1 | 12 | 30 | 75 | 12 | 3 |

| D12R1-40-100-3F MNR | 1 | 12 | 40 | 100 | 12 | 3 |

| D12R3-30-75-3F MNR | 3 | 12 | 30 | 75 | 12 | 3 |

| D12R3-40-100-3F MNR | 3 | 12 | 40 | 100 | 12 | 3 |

| D16R1-45-100-3F MNR | 1 | 16 | 45 | 100 | 16 | 3 |

| D16R1-60-150-3F MNR | 1 | 16 | 60 | 150 | 16 | 3 |

| D16R3-45-100-3F MNR | 3 | 16 | 45 | 100 | 16 | 3 |

| D16R3-60-150-3F MNR | 3 | 16 | 60 | 150 | 16 | 3 |

| D20R1-50-100-3F MNR | 1 | 20 | 50 | 100 | 20 | 3 |

| D20R1-70-150-3F MNR | 1 | 20 | 70 | 150 | 20 | 3 |

| D20R3-50-100-3F MNR | 3 | 20 | 50 | 100 | 20 | 3 |

| D20R3-70-150-3F MNR | 3 | 20 | 70 | 150 | 20 | 3 |

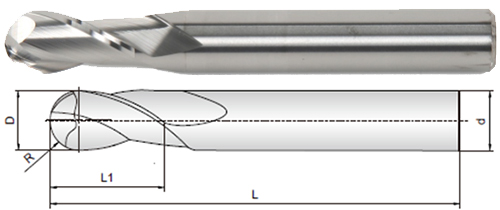

Non-coating.

Ultrafine particle cemented carbide .

Special cutting edge design with excellent

geometric angle.

| Specification | Rounded corner R | Dimentions (mm) | Number of cutting edges | |||

| Cutting diameter D | Cutting length L1 | Overall length L | Shank diameter d | |||

| D1R0.5-2-50-D4-2F MNB | 0.5 | 1 | 2 | 50 | 4 | 2 |

| D1.5R0.75-3-50-D4-2F MNB | 0.75 | 1.5 | 3 | 50 | 4 | 2 |

| D2R1-4-50-D4-2F MNB | 1 | 2 | 4 | 50 | 4 | 2 |

| D3R1.5-6-50-D4-2F MNB | 1.5 | 3 | 6 | 50 | 4 | 2 |

| D4R2-8-50-2F MNB | 2 | 4 | 8 | 50 | 4 | 2 |

| D4R2-8-75-2F MNB | 2 | 4 | 8 | 75 | 4 | 2 |

| D4R2-8-100-2F MNB | 2 | 4 | 8 | 100 | 4 | 2 |

| D6R3-12-50-2F MNB | 3 | 6 | 12 | 50 | 6 | 2 |

| D6R3-12-75-2F MNB | 3 | 6 | 12 | 75 | 6 | 2 |

| D6R3-12-100-2F MNB | 3 | 6 | 12 | 100 | 6 | 2 |

| D8R4-16-60-2F MNB | 4 | 8 | 16 | 60 | 8 | 2 |

| D8R4-16-75-2F MNB | 4 | 8 | 16 | 75 | 8 | 2 |

| D8R4-16-100-2F MNB | 4 | 8 | 16 | 100 | 8 | 2 |

| D10R5-20-75-2F MNB | 5 | 10 | 20 | 75 | 10 | 2 |

| D10R5-20-100-2F MNB | 5 | 10 | 20 | 100 | 10 | 2 |

| D12R6-24-75-2F MNB | 6 | 12 | 24 | 75 | 12 | 2 |

| D12R6-24-100-2F MNB | 6 | 12 | 24 | 100 | 12 | 2 |

Aluminium alloy —— Side milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

reflectal, cast aluminium alloy (Si<12%) |

ap≤1.5D | 150 (60-350) |

rotate speed (r/min) |

16000 | 12700 | 12000 | 10600 | 10000 | 9500 | 9280 | 7000 | 5600 |

| ae≤0.2D | feed speed (mm/min) |

650 | 850 | 1430 | 1530 | 1670 | 2050 | 2800 | 3000 | 3150 | |||

| copper alloy (HB200) |

ap≤1.5D | 150 (60-350) |

rotate speed (r/min) |

16000 | 12700 | 12000 | 10600 | 10000 | 9500 | 9280 | 7000 | 5600 | |

| ae≤0.2D | feed speed (mm/min) |

720 | 900 | 1200 | 1200 | 1500 | 1800 | 2225 | 2500 | 3000 | |||

Aluminium alloy —— Profiling milling

| workpiece material | cutting output (mm) |

Vc m/min |

Cutting diameter (mm) |

1 | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |

|

reflectal, cast aluminium alloy (Si<12%) |

ap≤0.3D | 150 (60-350) |

rotate speed (r/min) |

16000 | 12700 | 12000 | 10600 | 10000 | 9500 | 9280 | 7000 | 5600 |

| ae≤0.3D | feed speed (mm/min) |

650 | 850 | 1430 | 1530 | 1670 | 2050 | 2800 | 3000 | 3150 | |||

| copper alloy (HB200) |

ap≤0.3D | 150 (60-350) |

rotate speed (r/min) |

16000 | 12700 | 12000 | 10600 | 10000 | 9500 | 9280 | 7000 | 5600 | |

| ae≤0.3D | feed speed (mm/min) |

720 | 900 | 1200 | 1200 | 1500 | 1800 | 2225 | 2500 | 3000 | |||

| Carbide End Mills MG | for multi-material |

| Carbide End Mills MS | for heat-resisting alloys |